- Custom design

- From 1 meter onwards

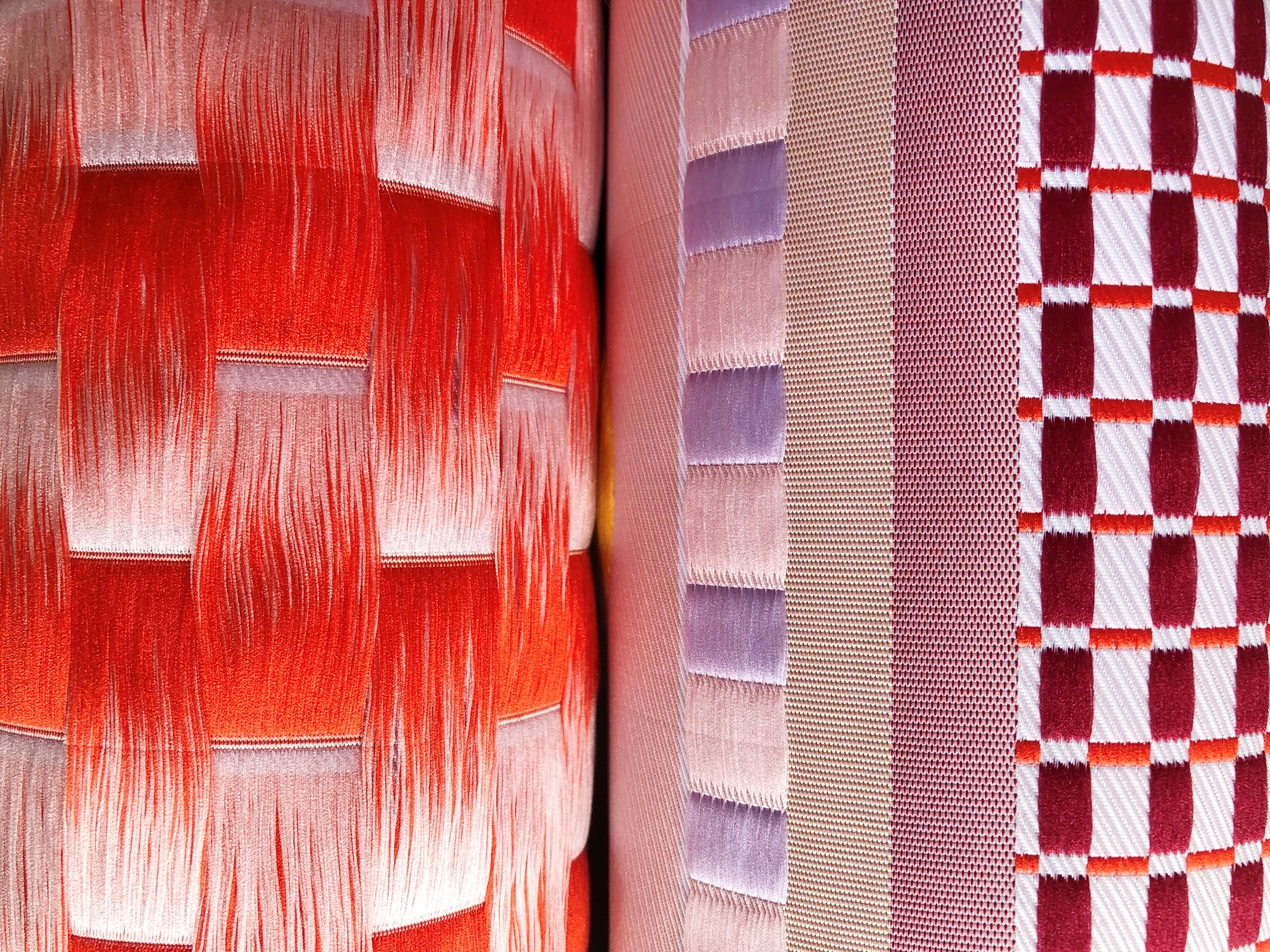

- Ultra-high definition jacquard

Story

3D

weaving

Weaving products directly on the machine

Our Master Jacquard Designer is trained as an artist and therefor thinks like on. She is specialised in the field of 3D weaving and technical solutions. With our custom made machines that have the most precise looms in Europe, with over 12.500 precision point in 150cm of width, we can create 3D woven products directly on the machine. We can split our warp into different layers by which we can create multi layered, 3D woven textiles.

Weaving seamless finished products

We strongly believe in the power of 3D weaving, which makes it possible to weave fashion and medical garments, interior products or accessories and replaceable sleeves for furniture or moulds for (the automotive) industries or prototypes directly on the machine, off the loom. It makes it possible to weave seamless finished products, this cuts out the conventional confection of products. Seams, pockets and sleeves can be programmed directly into the fabric.

3D weaving pioneers

As one of the pioneering partners in 3D weaving, we developed in 2015 the first 3D woven bag, which was exhibited during the Dutch Design Week in Eindhoven.

During the Covid-19 corona crisis, we developed a 3D woven washable mouth mask for the consumer market and developed a 3D woven medical gown prototype.

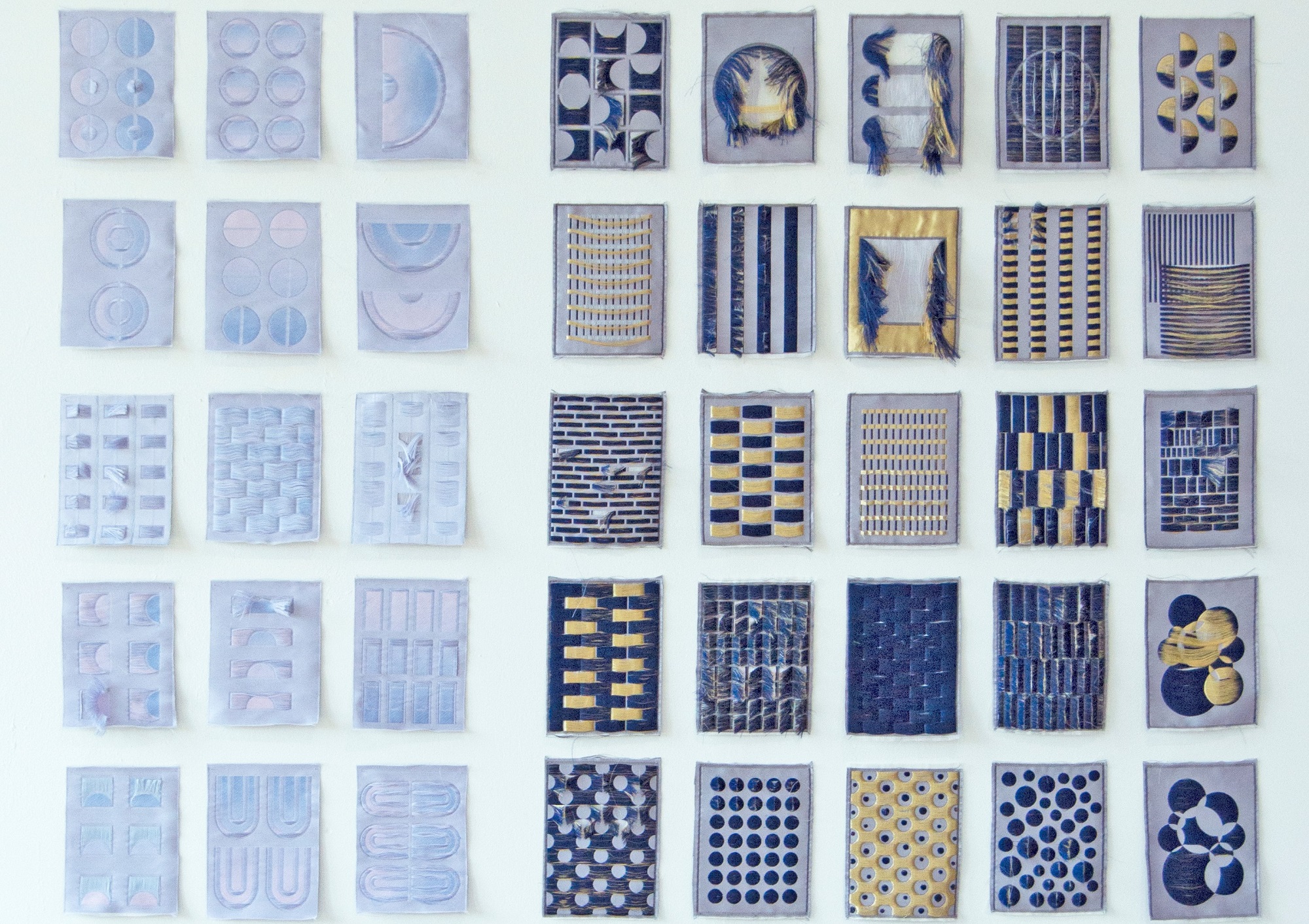

3D weaving research projects

We work continuously on research projects focussing on 3D weaving. In cooperation with designers and researchers we develop us further into this field to hopefully make it a realistic option for fashion designers in the near future.

Examples of products we could develop together with you in 3D weaving:

- 3D woven garments for fashion, medical, workwear

- 3D woven accessories like wallets, bags

- 3D woven interior products like lamps, shades, smart room-dividers

- 3D woven furniture sleeves as (replaceable) upholstery, pillows

- 3D woven flexible moulds for industries or prototypes

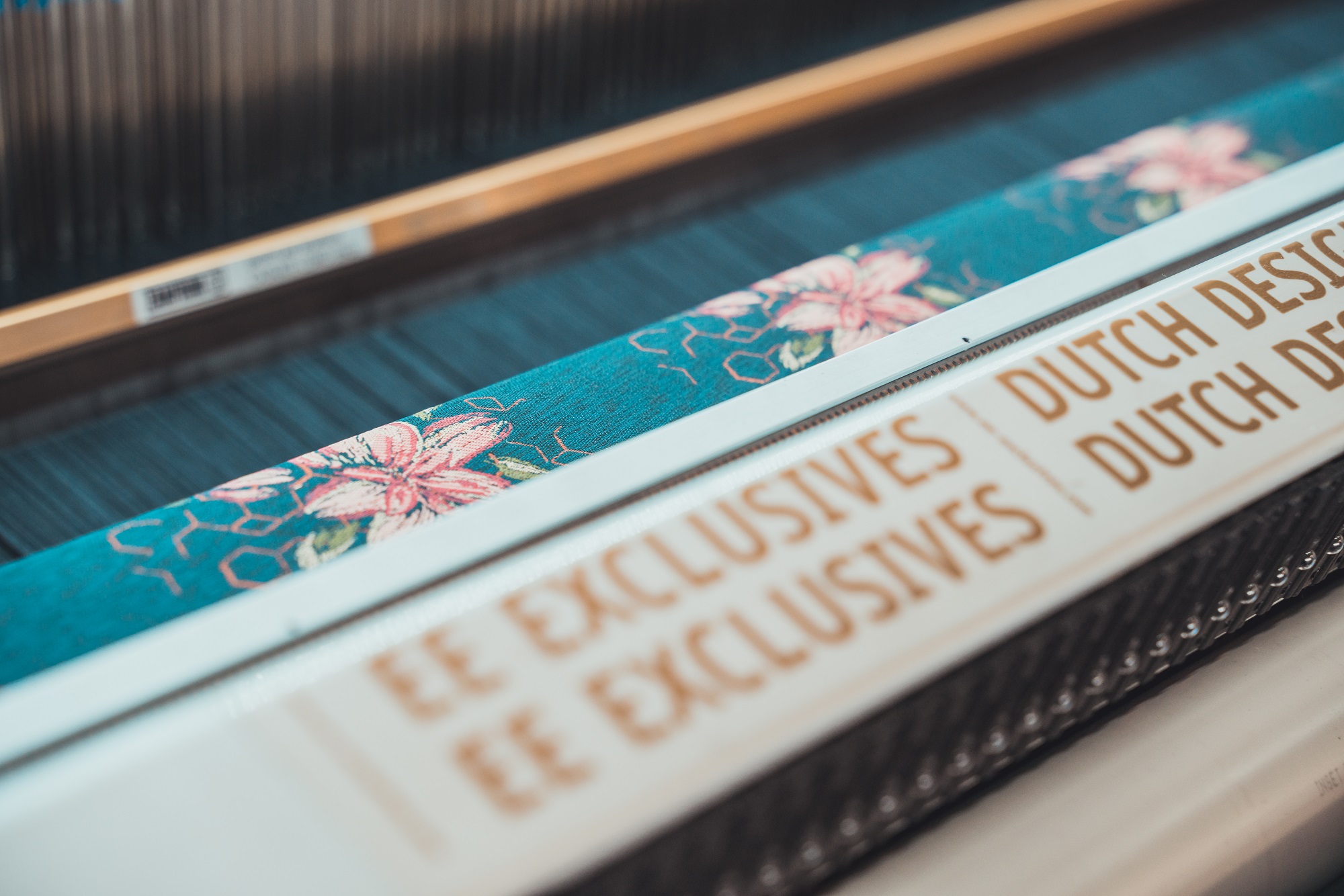

“A product is only finished with a nice label. Take a look at EE Labels for beautiful brand labels.”

Contactcontactimmediately

Do you have any questions after reading the options? Or would you like to receive more information about how EE Labels can help you? Our team of specialists is happy to assist you.

Art & fashion weareable artViktor & Rolf

Viktor and Rolf: one of the most important fashion houses from the Netherlands. The designer duo made a name for themselves with theatrical fashion shows and extravagant clothing collections. The duo had well-known paintings by Rembrandt translated into jacquard fabrics through EE Exclusives. Viktor and Rolf made a collection of dresses or works of art with these jacquard fabrics? After the fashion show, the fabrics hung on the wall as a beautiful painting. Is fashion art? The name of the collection says it all WEARABLE ART. One of the artworks was purchased by Museum Booijmans van Beuningen.

Read more